Product Description

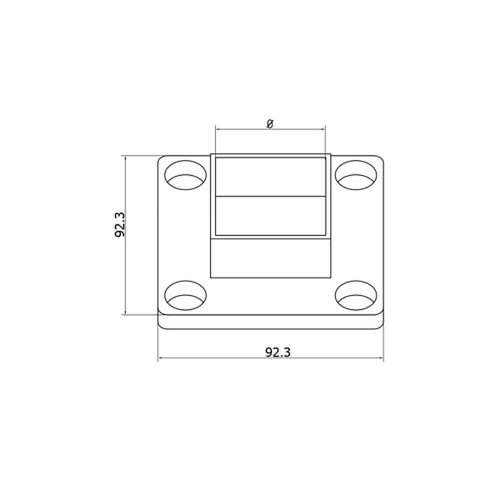

AX20.001.013.D.M Core Mount for 40 x 40 mm square post

- Material: AISI 304 stainless steel (high-grade, corrosion-resistant alloy for indoor/outdoor use).

- Finish: Satin polished (a brushed, low-maintenance surface that resists fingerprints and provides a subtle sheen).

- Dimensions: Designed to fit 40 mm x 40 mm square tubing (2 mm wall thickness). The core mount itself is a compact insert-style base, typically with an internal socket depth of approximately 100-150 mm.

- Weight: Approximately 2 lbs (lightweight for easy handling).

- Load Capacity: Engineered for structural railing applications; supports typical residential/commercial loads (up to 50-100 lbs per mount depending on configuration—consult local building codes for specifics).

- Compatibility:Part Number Breakdown: AX20 indicates the Square Series subfamily; 001.013 specifies the core mount variant.

- Pairs with 40 x 40 x 2 mm square posts (e.g., AX20.001.010.A.SP floor-mounted post).

- Works with flange covers (e.g., for level or angled floors) and handrail tubing.

- Suitable for glass, cable, or panel infills in the AXIA system.

- Tools: Drill with masonry/concrete bits (if embedding in concrete), level, tape measure, Allen wrench set (for set screws), torque wrench (optional for precision), hacksaw (for tube trimming), and adhesive applicator (for epoxy).

- Fasteners (House of Forgings Part Numbers):

- Concrete anchors: AX00.091.800.A.SP (expansion anchors or epoxy bolts for floors).

- Set screws for tube: Included or AX00.091.805.A.SP (M6/M8 stainless steel).

- Wood/metal screws if adapting: AX00.091.900.A.SP (wood) or AX00.091.905.A.SP (metal).

- Optional Accessories:Quantity: 1 core mount per post; scale for multiple.

- Flange cover (for level/angled concealment): Part not specified, but compatible with 100 mm base covers.

- 40 x 40 mm square handrail tube (for angled or no-flange setups).

- Epoxy adhesive or grout for core embeds.

- Measure and Plan: Determine post locations per railing design (e.g., every 4-6 ft for balusters). Ensure the floor/wall is level within 1/8 inch over 8 ft. Mark core mount positions using a template or laser level.

- Surface Prep: For concrete floors, clean and roughen the area. For wood subfloors, verify joist support. If using in an existing pour, plan embeds during concrete work.

- Cut Tubing (if needed): Trim square post or handrail tube to height using a hacksaw or pipe cutter. Deburr edges for smooth insertion.

- Embed the Core: Drill a 40 mm x 100-150 mm deep hole in the concrete floor at the marked position (use a core drill for precision). Insert the AX20.001.013.D.M core mount into the hole, ensuring it's plumb (use a level). Secure with epoxy adhesive, or construction adhesive.

- Insert Post/Tube: Slide the 40 x 40 mm square post or handrail tube into the core socket until it seats fully (typically 100 mm insertion depth).

- Secure the Connection: Tighten the internal set screws (using Allen wrench) to lock the tube in place. Torque to manufacturer specs (approx. 10-15 Nm to avoid stripping).

- Add Cover/Finish: Apply grout or a flange cover around the base for a seamless look. Caulk if needed for waterproofing.

- Test Stability: Apply lateral force to ensure no wobble; adjust if necessary.

- Prepare Base: Purchase compatible angled flange cover and 40 x 40 mm square handrail tube (cut to fit angle).

- Embed Core: As in Option 1, but angle the core mount to match the slope (use shims if needed). Secure with anchors/epoxy.

- Assemble Angled Section: Attach the handrail tube to the angled flange cover first (set screws), then insert the assembly into the core mount.

- Secure and Finish: Tighten set screws, add cover, and grout. Verify plumb with a level on the post top